Wearable for dynamic muscle ultrasound imaging

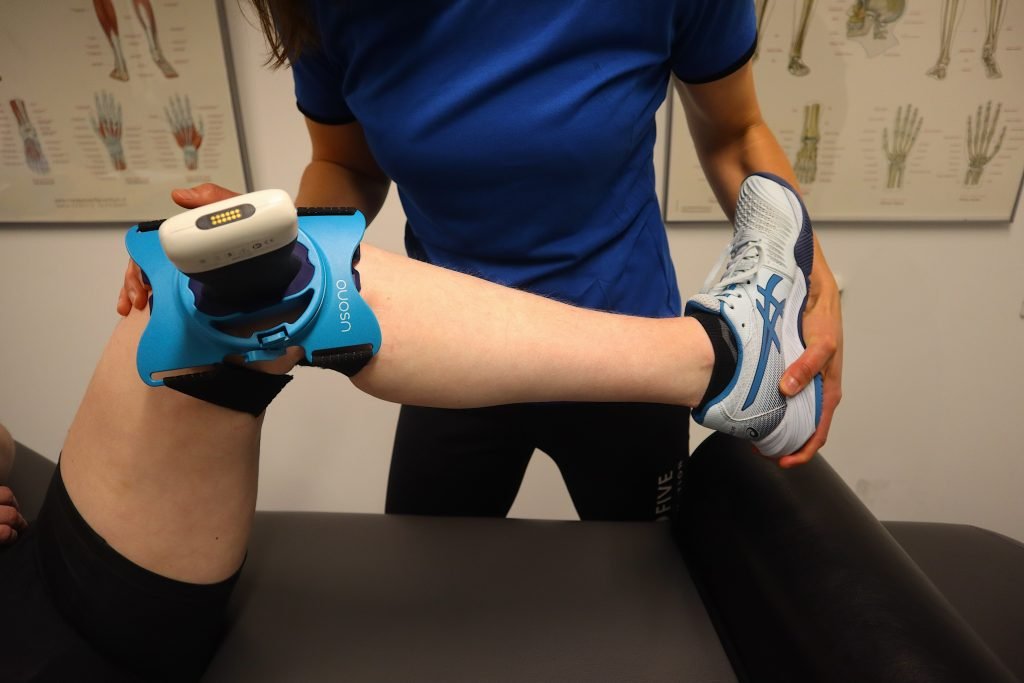

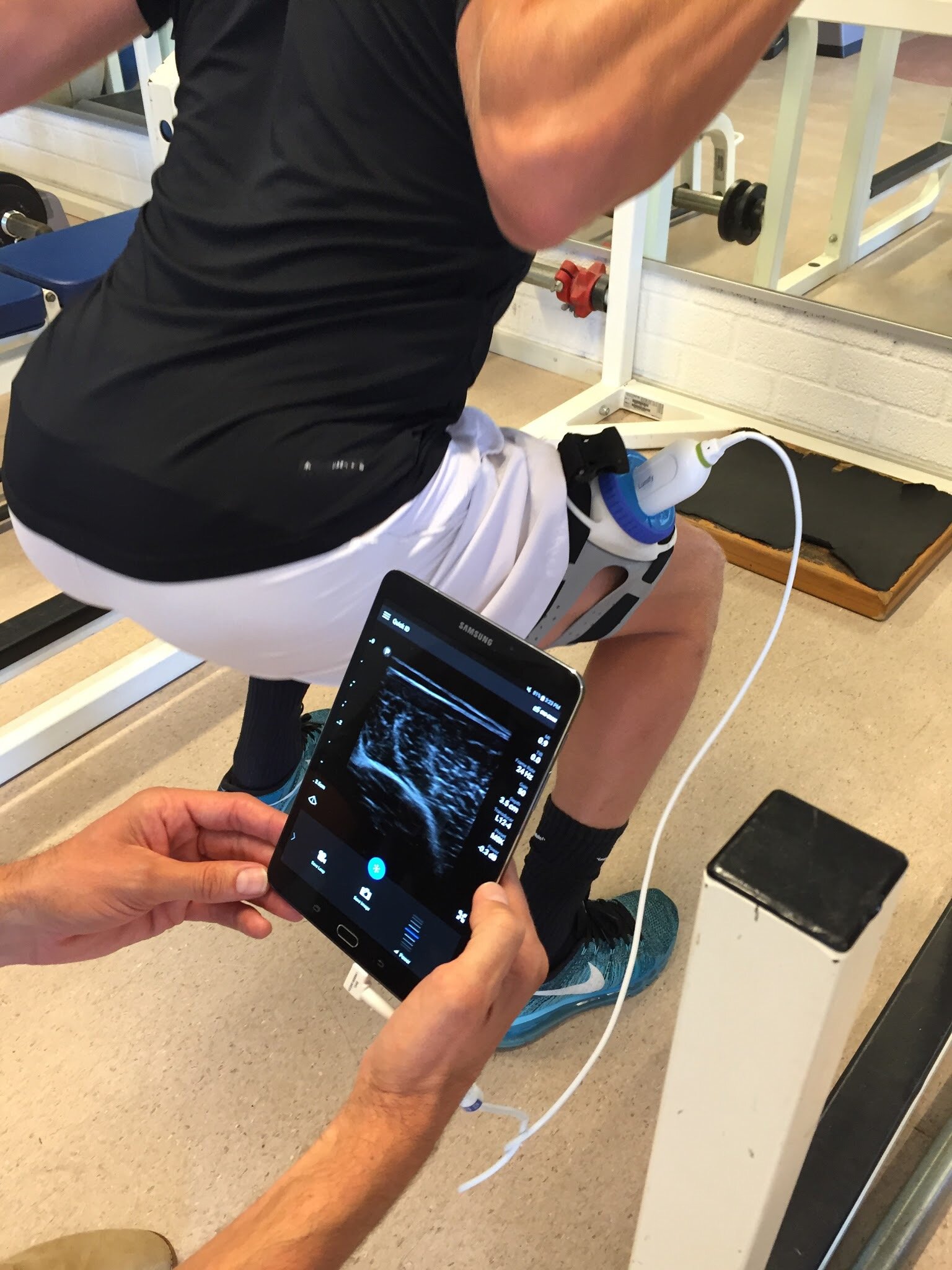

ProbeFix Dynamic is a new device that supports high-quality ultrasound measurements during dynamic exercise. The ProbeFix Dynamic keeps an ultrasound probe in place throughout intense movement. This can be used in sports training, muscle recovery exercises, during general rehabilitation practices, or even in intensive care departments.

Keywords: Project management. Research. Usability Design. User experience. Product design.

Designed for USONO - 2019/2020

Project brief

The objective of this project was to design a wearable device to fix the Philips Lumify probe, a wireless ultrasound system to the legs of sporters. The system had to be able to be worn during sports and physical activity. The device needed to be lightweight, stable, and comfortable to be worn during exercise and physical activity. Materials and shapes needed to comply with CE marking and FDA guidelines for medical devices. Due to the use of ultrasound equipment, metallic parts were not allowed for the construction of the device.

Contributions

I was responsible for the project management and product development team. This required me to coordinated the user research, prototyping, concept design, product design engineering (mechanical design and mould design for casting), and usability evaluation. As the company had almost no previous product design iterations, the design journey compiled a wide range of activities, starting at collecting and obtaining insights from users and initial explorations to technical and engineering development. Eventually, The project scope went from 3 months to almost one year.

Approach

Our first exploration consisted of creating multiple low-fi devices with soft and hard material, simulating the weight and feel of an ultrasound probe attached to the body. I made different prototypes using low cost materials and random objects as well as 3D printed parts to obtain insights on the key elements to consider at the moment of designing the wearable system, its attaching mechanisms and general shape.

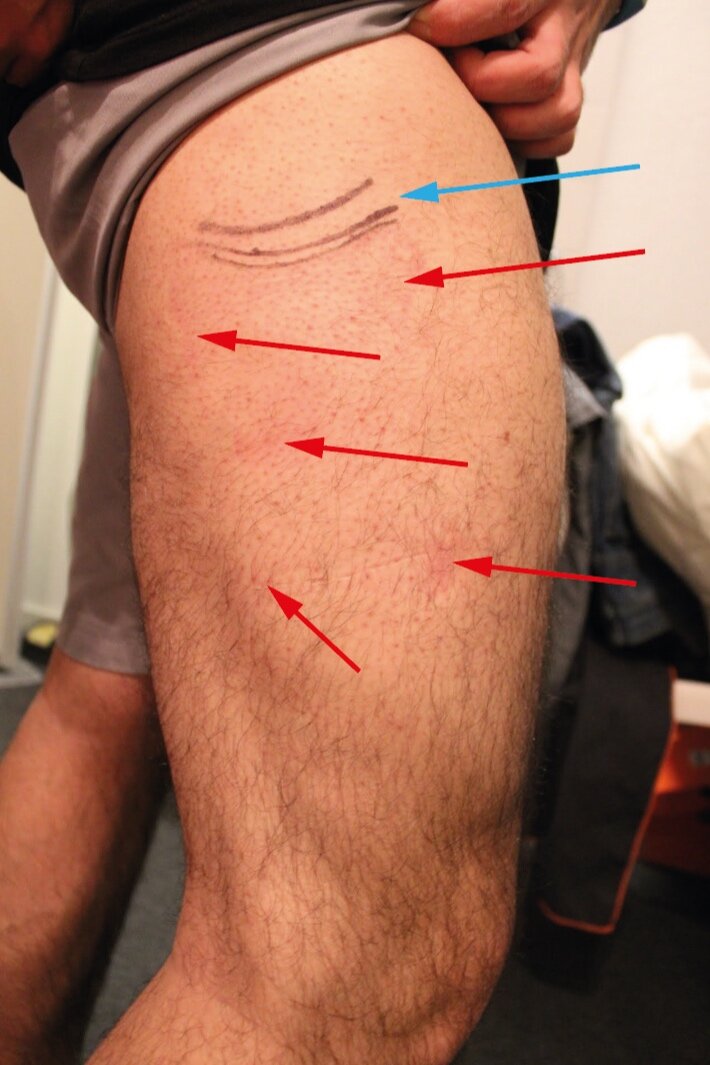

Different low-fi but functional prototypes were tested by members of the design team and by semi-professional dutch football and hockey players. We noticed that these first iterations of the design were rather heavy and not stable enough for the system to capture good ultrasound images. Furthermore, the contact surface was rather big, limiting the range of motion of the body. Keeping the wearable fixed in place was a major issue.

Concept design

Using the insights from the initial approach, we went back to the ideation table. We produced several sketches and design ideas. I synthetysed the insights an ideas into a visual concept design. The focus of this process was to define then ideal shape for the device to fit on the body will providing sufficient stability and fixation for capturing the ultrasound imaging.

Based on the previous 2D and 3D explorations, we defined three main concept designs to be explored further. My primary job in this stage was the design and modeling of the device, optimize it for high-quality 3D printing, reduce its volume and weight, and ensure its biocompatibility compliance from a anthropometric and manufacturing perspective. To improve the grip and feel of the device on the skin, a set of different silicone pads were designed. The project scope went from 3 months to almost one year.

To improve the grip and feel of the device on the skin, a set of different silicone pads were designed. The objective of these pads was to provide a soft and non-slippery grip mechanism between the skin and the device.

Multiple iterations of the device were tested on the field. These tests focused on finding the balance between comfort, stability, and proper imaging recording. It became a major challenge to comply with the three aforementioned requirements. For instance, tight straps were optimal to reduce oscillation and displacement but detrimental to image quality due to the abnormal compression of the muscles. Smaller (sharper silicone feet) proved to be more effective to keep the device in place during prolonged exercise routines, but painful to be worn.

To reduce localized pressure on the muscles and increase grip and stability, larger and deformable silicone pads were designed. I was responsible for the mechanical simulations and user tests to define the most optimal structure for the silicone pads. Besides my leading role, I was also responsible for supervising and supporting the manufacture partner, including the optimisation of mould for plastic injection and silicone casting, as well as the delivery of files ready to for 3D printing.

The last phase of the development process focussed on the designed and adjustment of the mechanical assembly between the different parts of the system. We designed a patent-pending system that uses the mechanical properties of the ABS to secure, release and configure the device in different positions of use.

For details www.usono.com